- Home

- About Us

- Products

- Service

- Project

- News

- Contact Us

Pulished on Sep. 26, 2023

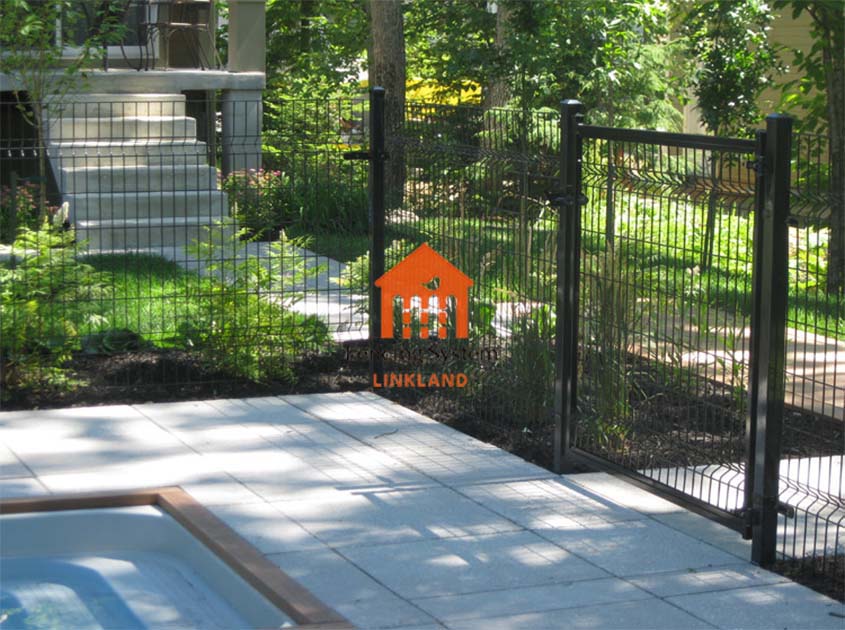

Welded mesh fence systems are flexible and adaptable security features used in a wide variety of industrial facilities. These fences are usually made of high-strength steel and are welded to form a grid-like structure that has high impact resistance and anti-climbing capabilities.

Welded mesh fence systems play a variety of important roles in industrial facilities. First, they can serve as a physical barrier to prevent the illegal entry or exit of people and objects. Due to their grid-structured design, these fences are difficult to pass through or around, whether on foot or by car. Secondly, the Welded mesh fence system can also be used as part of a security system, combined with monitoring equipment and alarm devices, to improve the safety of the entire industrial facility. At the same time, they can also be used as a sign or boundary to delineate the boundaries and areas of the facility to prevent misoperation or entry.

The custom design of welded mesh fence systems is of great significance in industrial facilities. Since various industrial facilities vary in size, nature and security needs, the design of fencing systems can be customized to the customer's specific needs and requirements. For example, parameters such as fence height, grid density, and materials can be adjusted according to the facility's architectural structure, topography, usage functions, etc. In addition, additional functional modules can be added to the fence, such as billboards, lighting equipment, etc., to meet the special needs of customers.

The custom design and production of welded mesh fence systems require compliance with certain specifications and standards. Designers need to determine the design and manufacturing plan of the fence based on national and regional laws, regulations and industry standards. At the same time, compatibility with other equipment and buildings in the industrial facility also needs to be considered to avoid problems caused by incompatibility. During the production process, quality and safety need to be strictly controlled to ensure that each welding point is strong and reliable, and the entire fence system is safe and effective.

Welded Wire Mesh for Middle East Construction Projects

Pulished on Feb. 06, 2026

How to Select Chain Link Fence for Middle East Applications

Pulished on Jan. 26, 2026

How to Package Wire Mesh for Long-Distance Shipping to South America

Pulished on Jan. 16, 2026

What Is the MOQ for Wire Mesh Products from Chinese Manufacturers?

Pulished on Jan. 13, 2026

What Wire Diameter Is Best for Welded Mesh?

Pulished on Jan. 13, 2026

How to Ensure On-Time Delivery of Wire Mesh to the Middle East

Pulished on Dec. 30, 2025

What Quality Standards Are Required for Wire Mesh Fence in South America?

Pulished on Dec. 25, 2025

How to Choose a Reliable Wire Mesh Fence Manufacturer in China?

Pulished on Dec. 22, 2025

Welded Wire Mesh for Middle East Construction Projects

Pulished on Feb. 06, 2026

How to Select Chain Link Fence for Middle East Applications

Pulished on Jan. 26, 2026

How to Package Wire Mesh for Long-Distance Shipping to South America

Pulished on Jan. 16, 2026

What Is the MOQ for Wire Mesh Products from Chinese Manufacturers?

Pulished on Jan. 13, 2026

What Wire Diameter Is Best for Welded Mesh?

Pulished on Jan. 13, 2026

How to Ensure On-Time Delivery of Wire Mesh to the Middle East

Pulished on Dec. 30, 2025

What Quality Standards Are Required for Wire Mesh Fence in South America?

Pulished on Dec. 25, 2025

How to Choose a Reliable Wire Mesh Fence Manufacturer in China?

Pulished on Dec. 22, 2025

EN

EN SP

SP FR

FR